The following story is the first of a two-part series and looks at limits to innovation in lithium-ion batteries. The second part of the series will unpack the future of battery chemistries over the coming decade.

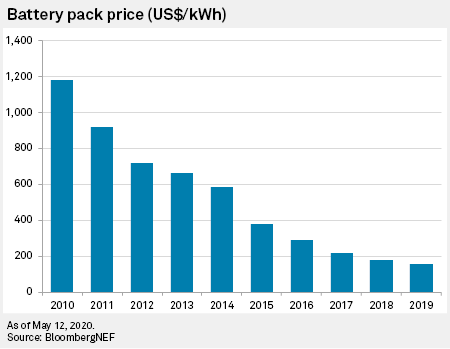

Mainstream lithium-ion batteries, now driving a rapidly expanding market for electric vehicles, were a pricey proposition just a decade ago. Lithium-ion battery packs cost US$1,183 per kilowatt hour in 2010; nine years later, the price had dropped nearly tenfold to US$156/kWh in 2019, according to BloombergNEF data.

The pace of the cost decline caught battery experts off guard, including analyst James Frith, BloombergNEF's head of energy storage. "They've come down faster than I have been forecasting each year," Frith said. "That is certainly surprising."

Rebecca Ciez, a postdoctoral fellow at Princeton University's Andlinger Center for Energy and the Environment who researches battery costs, agreed. "The more recent drop is pretty dramatic," Ciez said. "It's surprising how the market shifted so quickly."

Experts pointed to momentum in expanding production as a reason for the price drop as well as incremental innovation in battery chemistry. Manufacturers have been shifting away from some more expensive battery ingredients such as cobalt as they ramp up nickel-heavy battery designs that have become cheaper to produce as factories expand.

Ciez noted that a decade ago, the electric vehicle market was just coming under pressure to build cars and trucks in places where carbon emissions were starting to be regulated, such as in California. "So you had these compliance cars where manufacturers said, 'OK, we've got to make this [Toyota] RAV4 electric,'" Ciez said, using a fossil fuel-powered car as an example. "And so they would just slap together a bunch of laptop batteries that were readily available."

Since then, the battery sector has made huge strides in driving down costs, tweaking materials in batteries to use cheaper and less ethically questionable metals while capturing economies of scale.

US$100/kWh is the holy grail

Manufacturers are closing in on a point where electric vehicles will reach cost parity with their fossil fuel-powered cousins at around US$100/kWh, or perhaps a little less, experts said. That price is widely seen as a tipping point in the sector, where consumers will no longer regard electric vehicles as pricier options.

BloombergNEF forecast battery costs falling under US$100/kWh in 2024 and hitting around US$60/kWh by 2030, Frith said. Likewise, Bernstein analysts have projected 2024 as the year that mainstream electric vehicles reach cost parity with gas and diesel vehicles, while electric vehicle leaders in the sector may reach the same point by 2022 or 2023.

While this will be accomplished without major innovations in lithium-ion batteries, mature lithium-ion technology is fast approaching limits to how much it can be improved, experts told S&P Global Market Intelligence. One battery chemist, a leading lithium-ion battery scientist who has conducted research for a major electric-vehicle maker that depends on the technology, said lithium-ion batteries have started to max out on certain fronts such as price, energy density and charging speed.

"There's no giant boost coming along," the chemist said. From his point of view, incremental improvements may be enough to satisfy consumers, while any battery revolutions from unproven technologies remain years off.

"You can do really well with lithium-ion batteries today," he said. "And in helping to bring the cost down — that's going to improve the market penetration of the whole technology."

Venkat Viswanathan, associate professor in the Department of Mechanical Engineering at Carnegie Mellon University, agreed the technology is nearing its limits. He expects that lithium-ion battery prices could still decline by about 20% and 30% but that they will not likely get much cheaper.

"We're quickly approaching the limits of raw material costs," Viswanathan said.